“The Natural Evolution”, the story of EUROJERSEY’s Sustainable Enterprise: From corporate vision to higher efficiency and low environmental impact.

Since 2007 EUROJERSEY, the Italian leader in the manufacture of warp-knit Sensitive® Fabrics, has been committed to sustainability through its SensitivEcoSystem® project. The Company now presents “The Natural Evolution”, a new book on the natural development of its Sustainable Enterprise.

“The Natural Evolution” is the story of a project inspired by an ambitious mission: to convert cost into value and turn investments in latest generation machinery into an efficiency advantage, with lowest environmental impact. The development of a vertical supply chain with no outsourcing has enabled EUROJERSEY to maintain control over the entire Sensitive® Fabrics production process in its Caronno Pertusella (Va) mill, generating positive effects on the local economy and environment. In short, a specific example of production development conveniently suited to the local level and Made in Italy value.

The SensitivEcoSystem® project, which benefits from the involvement of clients, suppliers and consumers, contributes to the creation of a successful sustainable supply chain, enabling savings and recovering and streamlining resources.

The use of cutting-edge equipment and technology has led to many benefits for the local economy and environment, including a significant reduction in energy consumption of 700,000 kWh/year (8% of the total, with 20,000 kWh produced by the company itself from solar panels), the equivalent of 400 tonnes less CO2 being released into the atmosphere in one year, as well as savings in water use of 30 million litres generated by the internal purification and re-use plant. Recyclable waste management – including cellophane and textile waste recovery – has also produced excellent results, with a total of 47,000 kg of material transformed from waste into highly valuable raw materials.

Also, the ECO-PRINT technology developed by EUROJERSEY has led to significant environmental benefits, like a 50% reduction in water consumption and a 25% cut in energy use compared to traditional print methods.

All this has enabled the Company to obtain the most important international certifications (EPD Environmental Product Declaration, Climate certification, ISO 14001 and Oeko Test), recognising EUROJERSEY’s commitment and achievements towards sustainable development.

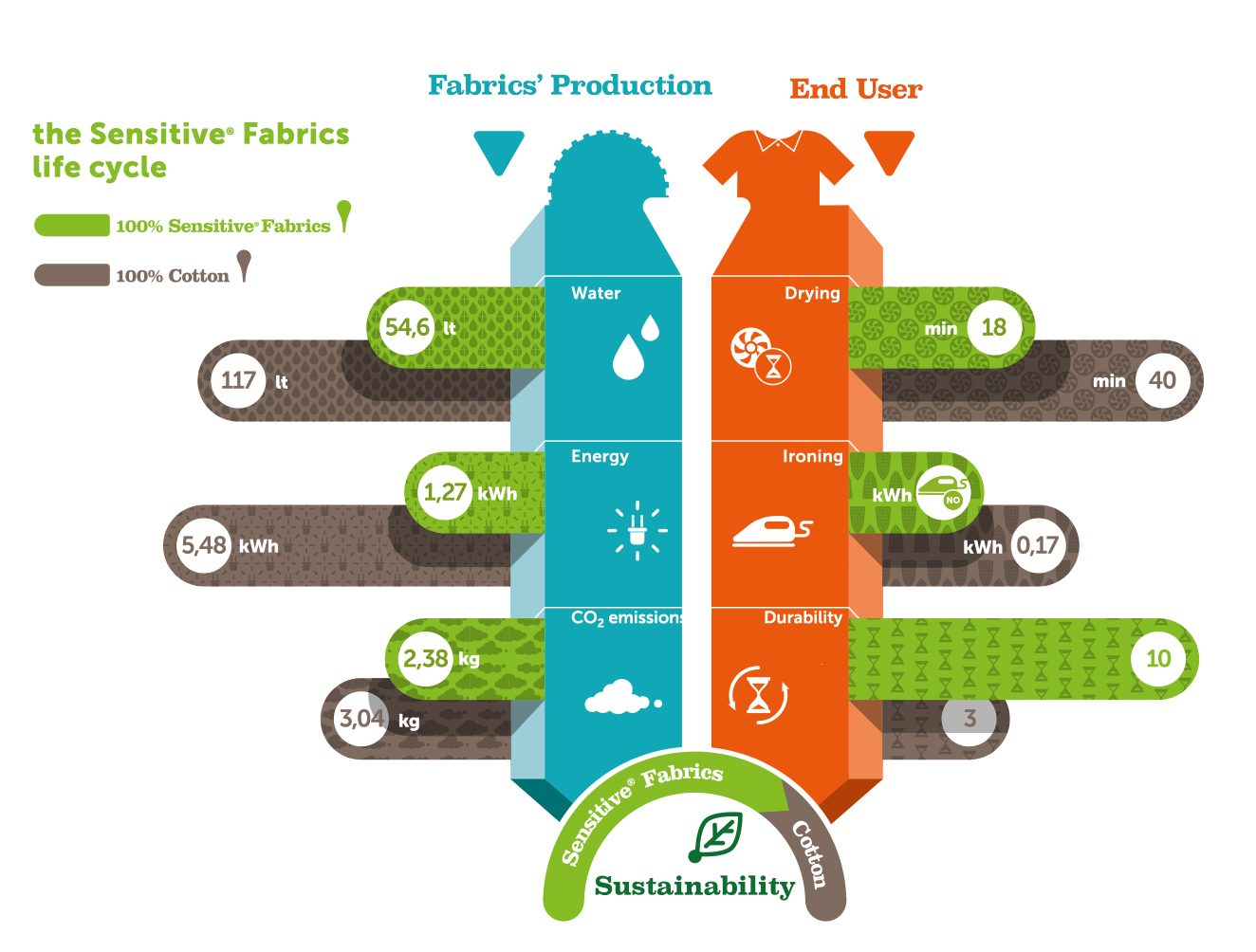

Most importantly, the end consumers can benefit from knock-on effects with regard to the lifecycles of Sensitive® Fabrics (Life Cycle Impact Assessment – LCIA), as buying a garment made with these fabrics is a deliberate focus on sustainability. The garment will have a longer-than-average life cycle because it is more resistant, offering higher performance and a lower impact on the environment.

EUROJERSEY Spa, founded in 1960, is a reference point in the sector of Italian-made warp knit fabrics, thanks to its patented range called Sensitive® Fabrics. An expression of the most advanced textile knowledge combined with a constant quest for the highest quality. The Company today has a unique vertical production plant in Europe, designed by the famous Italian architect Antonio Citterio, with a team of 187 people providing a pioneering example of efficiency and sustainable quality with an annual production capacity of 15 million metres of fabric.

Sensitive® Fabrics combine the unique qualities of Italian style, chosen by major world-wide brands in underwear, swimwear, sportswear and readytowear.

The manufacturing methods, developed and patented by EUROJERSEY itself, allow the creation of the highest quality in solid colours and printed fabrics using innovative techniques which enhance the creativity of design and performances.

For more information please visit EUROJERSEY | Sensitive® Fabrics | www.sensitivefabrics.it

Tags: 2015, books, Eco System, EUROJERSEY, fabrics, fashion, fashion design, Sensitive, Sensitive Fabrics, sustainability, Sustainable, textiles

Share On Facebook

Share On Facebook Tweet It

Tweet It

Share on LinkedIn

Share on LinkedIn